Force driven actuator

1. Structure

The force driven actuator consists of an actuator, a lever feedback mechanism, a staggered throttle, and a cylinder. Based on the combination and expansion of basic structure and working principle, various types of force driven actuators can be formed and applied to different types of steam turbine control systems.

2. Characteristic

1) The force driven actuator is a force balance system controlled by mechanical force transmission, without traditional hydraulic amplification mechanisms for pulsating oil transmission control signals. It is a hydraulic control system without hydraulic control working fluid;

2) Improved tracking power and oil pollution resistance of the wrong throttle spool valve;

3) Adopting a lever feedback and high torque balance system, it appears to be a rigid structure with high positioning accuracy and anti-interference ability:

4) The static balance of the wrong throttle spool valve is only controlled by the output force of the REXA actuator, and the fluctuation of system oil pressure has no impact on the static balance of the spool valve, thus possessing high working stability and anti oil pressure interference ability.

3. Overspeed limit and protection system

3.1 Overspeed limit system (OPC): Equipped with OPC overspeed limit valve group, OPC electrical

3.2 Protection System (OPT): Equipped with redundant OPT solenoid valve groups, redundant safety oil pressure switches, and other OPT system structures.

4. System Characteristics

1) The system structure is simple, the construction workload is small, and installation, maintenance, and debugging are convenient;

2) The conversion device does not require external control oil sources and oil purification devices, simplifying the system structure;

3) The system has strong resistance to oil pollution and interference from oil sources, and has high stability;

4) Improved the tracking force of the wrong throttle of the hydraulic servomotor, which is conducive to preventing the spool valve from getting stuck and improving reliability;

5) The system has high positioning accuracy, which is not affected by mechanical friction, power supply, oil pressure, oil temperature and other conditions;

6) The protection system has a simple structure and adopts multiple redundant designs, ensuring high operational safety of the unit;

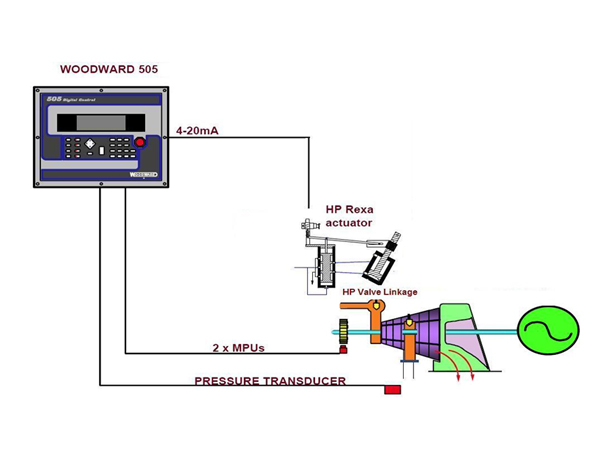

7) Adopting 4-20mA standard control signals, easy to accept control signals from any control system;

8) When the DEH controller malfunctions or the control system loses power, it has an automatic position protection function to maintain the valve position and load unchanged. Therefore, in the event of a control system malfunction, it can still ensure power generation and reduce non shutdown accidents of the unit;

9) Can achieve online maintenance or replacement of REXA actuators;

10) Suitable for various working fluid DEH systems such as fire-resistant oil and turbine oil.

.jpg)

024-23788883

024-23788883