System maintenance

1.Inspection standards

1)Power industry standard DL/T 838 "Guidelines for Equipment Maintenance of Power Generation Enterprises";

2)Power industry standard DL/T 711 "Guidelines for Testing Steam Turbine Control Systems";

3)Power industry standard DL/T 824 "Guidelines for performance acceptance of steam turbine electro-hydraulic control systems;

4)The company's enterprise standard QB/LEPCT-001 "Technical Specification for Maintenance of Steam Turbine Fire-resistant Oil DEH System".

2. Maintenance process flow

1)Assist in the disassembly, packaging, and transportation of the equipment to be inspected;

2)Equipment disassembly inspection and cleaning;

3)Repair and replace worn parts;

4)Replace seals and filter elements;

5)Performance test after equipment maintenance

6)Guide equipment installation, reset, debugging, and on-site acceptance.

3. Maintenance items

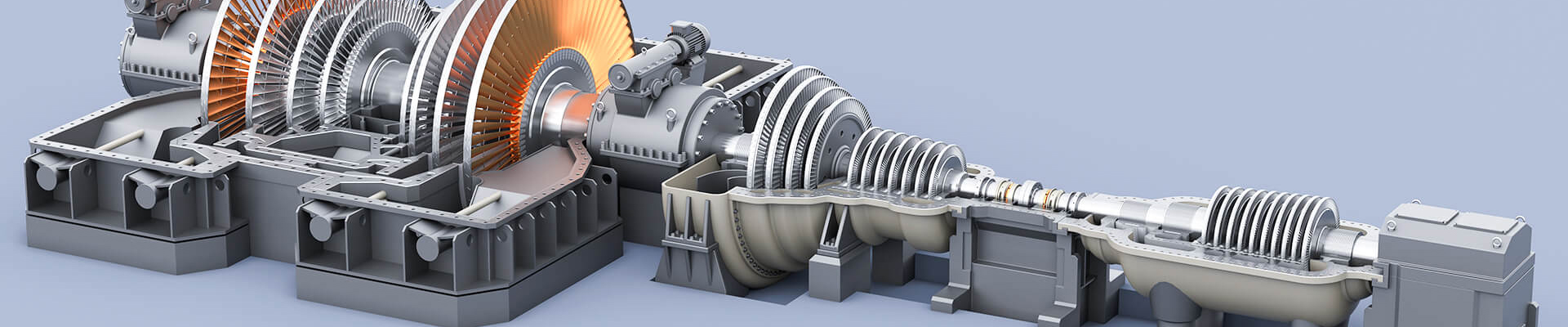

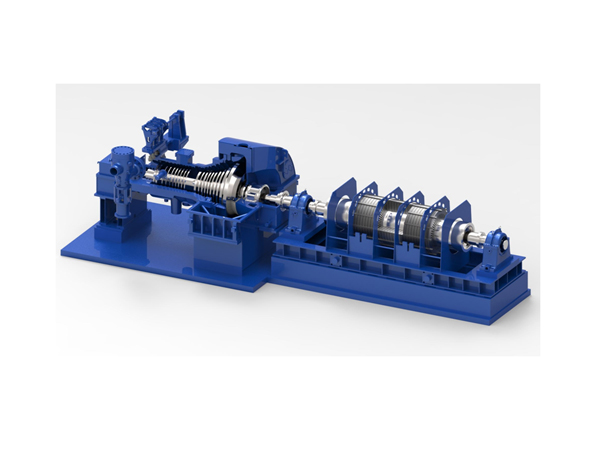

3.1 EH oil supply system

1) Disassembly and repair of EH oil pump, circulating pump, and regeneration oil pump;

2) Accumulator maintenance;

3) EH oil tank cleaning;

4) Maintenance and replacement of seals and filter elements.

3.2 Hydraulic Servomechanism

1) Repair and maintenance of the main throttle valve, regulating valve cylinder body, piston, piston ring, and guide sleeve

2) Cleaning and maintenance of the oil circuit of the oil cylinder control integrated block;

3) Maintenance and adjustment of electro-hydraulic servo valves;

4) Maintenance and repair of solenoid valves, quick unloading valves, and shut-off valves;

5) Repair and replacement of seals and filters.

3.3 Security System

1) Maintenance of emergency trip systems and components;

2) OPC, AST integrated block, solenoid valve component oil circuit cleaning and maintenance;

3) Diaphragm valve maintenance;

4) Maintenance and replacement of seals.

4. Testing and testing items

1) EH oil pump performance test: detect flow rate, pressure, internal leakage, and external leakage;

2) Performance testing of electro-hydraulic servo valves: detecting characteristics such as flow rate, pressure gain, zero internal leakage, and zero external resolution;

3) Comprehensive performance test of hydraulic Servomechanism: oil cylinder running in test, pressure test, actuator action characteristic test, fast closing time test, pressure test;

4) Comprehensive performance tests for OPC, AST integrated blocks, and solenoid valve components: action test, functional test, and withstand voltage test;

5) Accumulator inflation pressure adjustment and pressure test;

6) Performance testing of diaphragm valves.

5. Technical Services

5.1 Steam turbine DEH system safety operation guarantee service

1) Operation guarantee: Provide year-round technical services for the DEH control system, EH system, and security system of the power plant steam turbine to ensure the safe and stable operation of the unit;

2) Provide training services: provide technical training on principles, functions, and maintenance based on needs;

3) Provide operation maintenance and inspection supervision services: regularly maintain and inspect important components, supervise and maintain the oil quality of the EH system, and inspect and test the protection system;

4) Provide fault diagnosis and handling services: detect and analyze faults in control systems, hydraulic systems, and security systems, provide timely solutions and handling, and ensure the safe and stable operation of the unit.

5.2 Spare parts

We can provide various spare parts and accessories within the scope of turbine fire resistant oil EH system.

6. Performance

1) The inspected EH system basically covers various types of EH systems and equipment operating in China;

2) The tested EH system units have a capacity of 100MW, 125MW, 135MW, 150MW, 200MW, 300MW, 330MW, 350MW, 600MW, etc., as well as the feed pump turbine EH system;

3) Manufacturers of EH system units under inspection: various types of units produced by Haqi, Dongqi, SAIC, Wuqi, Nanqi, Westinghouse, Mitsubishi, Alstom, the former Soviet Union and other manufacturers;

4) We have provided year-round technical services to the power plant, ensuring the safe and stable operation of the unit, and achieving significant benefits for the power plant.

.jpg)

024-23788883

024-23788883