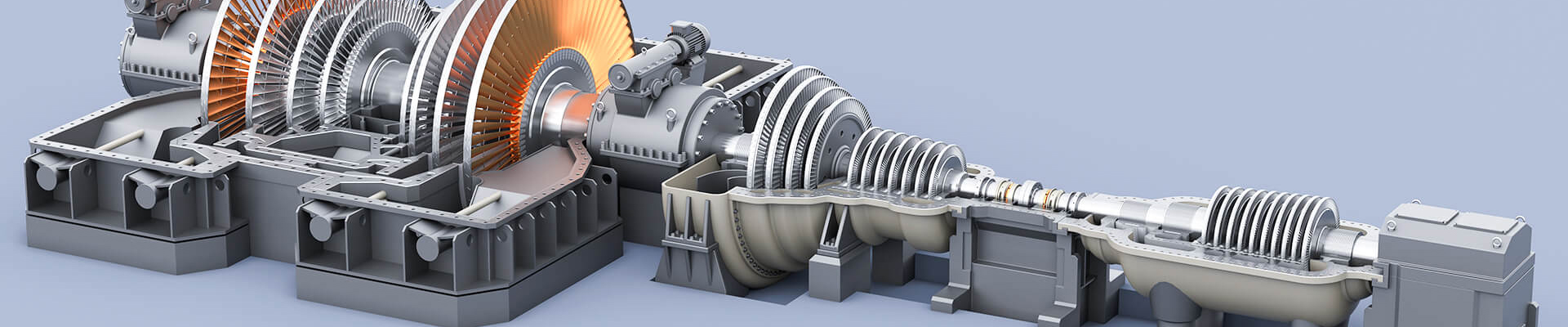

System Component Testing

1. Inspection and testing standards

Power industry standard DL/T 838 "Guidelines for Equipment Maintenance of Power Generation Enterprises";

Power industry standard DL/T 711 "Guidelines for Testing Steam Turbine Control Systems";

The power industry standard DL/T 824 "Guidelines for Performance Acceptance of Turbine Electro hydraulic Regulating Systems".

2. Testing and testing equipment

The quality inspection center has a first-class comprehensive testing station in China:

Comprehensive Test Station for Large Regulating Systems;

Large oil system comprehensive testing station;

Multifunctional overspeed test bench for steam turbines;

Adjusting part set test bench;

Main oil pump test bench;

Electrohydraulic servo valve and servo system performance test bench;

Valve, pump, cylinder test bench, etc.

3. Scope of inspection and testing

1)According to the relevant standards of the power industry, 61 items of 9 types of products can be inspected, and the inspection data issued by them have legal effect and can be used as the basis for trade certification, product quality evaluation, and achievement appraisal.

2)Turbine hydraulic (mechanical) regulation system and equipment debugging and performance testing;

3)Steam turbine DEH system and equipment debugging and performance testing

4)Conduct inspection, testing, adjustment, and identification of various hydraulic systems, equipment, and components using fire-resistant oil or wear-resistant hydraulic oil as the working medium;

5)Factory testing, adjustment, testing, and identification of the adjustment unit set in the manufacturer;

6)Diagnosis, analysis, and handling of faults in the regulation, security, oil system, and components of in-service units;

7)Technical supervision of steam turbine regulation;

4. Testing and testing items

4.1Turbine governing system and components

1)Mechanical (hydraulic) governor;

2)Mechanical (hydraulic) Pressure regulator;

3)Hydraulic servo motor, electro-hydraulic Servomechanism;

4)Mechanical crisis interrupter;

5)Automatic shutter;

6)Hydraulic differentiator

7)Oil ejector;

8)Main oil pump, lubricating oil pump;

9)Governor spool valve and intermediate spool valve;

10)Emergency trip spool valve; Oil overflow valve and fire slide valve;

11)Oil powered mechanism shutdown time test。

4.2 Hydraulic systems and components using fire-resistant oil or wear-resistant hydraulic oil as the working medium.

1)Electro hydraulic servo valve;

2)Pressure Control Valve; Servo valve, control valve

3)Flow control valve;

4)Directional control valve;

5)Hydraulic Cylinder。

5. Performance

1)The inspected systems and equipment basically cover various types of regulating systems in service in China;

2)The regulation, security and oil system components (such as governor, Pressure regulator, emergency protector, hydraulic servo motor, automatic shutdown device, differentiator, oil ejector, oil spill valve, etc.) of 7 steam turbine manufacturers have been inspected, tested and identified before delivery;

3)Diagnosed and analyzed the faults of the regulating system and components of the in-service unit, and verified their resistance through testing. Dealed with the causes of enemy obstacles, such as the analysis and modification of the main oil pump fault of the 200MW unit; Fault analysis and optimization design of oil ejector for 200MW and 600MW units; Renovation of the execution mechanism of the DEH system for a 300MW unit. Provided guarantee for the safe operation of the unit;

4)Routine maintenance and testing have been carried out for the overhaul of the regulating system and components of the in-service units;

5)We have conducted inspections, tests, adjustments, and evaluations on hydraulic equipment and components produced by domestic and imported companies such as MOOG, VICKER, REXROTH, ABEX, ATCHLEY, DOWTY, CSD, YFW, EMG, etc;

6)Conducted a large number of quality supervision and testing work on hydraulic control components;

7)As the only hydraulic control system testing organization in the power industry of China, our company has established the image of an authoritative, scientific and impartial third-party laboratory in the power industry with its professionalism, progressiveness and strong technical strength, and has formed a certain popularity and influence in China. Based on serving the power industry, we have developed a broader market and have entered industries such as metallurgy and chemical engineering. Expand the detection range, utilize its own advantages, and serve the vast number of users.

.jpg)

024-23788883

024-23788883