Complete Design

The company has senior design talents specializing in hydraulic systems and complete testing equipment for hydraulic systems and components, which can ensure the correctness, practicality, and reliability of system design and equipment manufacturing.

To optimize the design and provide technical support and services for the problems in the turbine oil system of in-service units.

At present, more than 30 sets of products such as turbine oil system, jacking oil system, and integrated oil tank have been provided for Jifa.

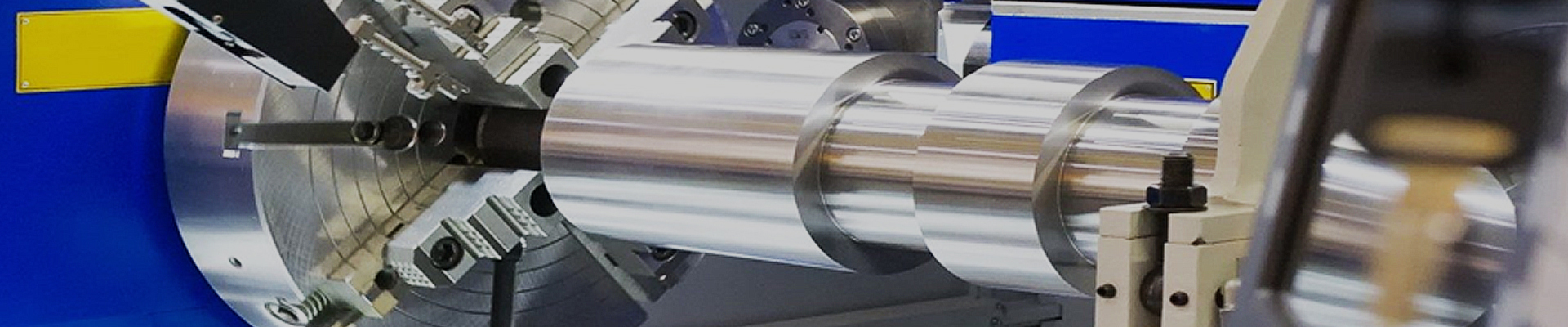

Turbine oil system

The oil system is an important component of the steam turbine generator set, responsible for bearing lubrication, regulating the power oil source of the system, and supplying oil to the steam turbine security system. Our company focuses on the power industry and implements the design, manufacturing, assembly, engineering, and technical support of steam turbine oil systems. The company has senior design talents specializing in hydraulic systems, complete and advanced design methods, and complete hydraulic system and component testing equipment. Combining detailed design, manufacturing, assembly, and experimental verification to ensure the correctness, practicality, and reliability of system design, equipment manufacturing, and assembly.

1. Scope of design and complete set

1) Design, manufacturing, assembly, debugging, and technical support of the turbine oil system for steam turbine generator units;

2) Design, manufacturing, assembly, debugging, and technical support of the DEH fire-resistant oil system for steam turbines;

3) Design, manufacturing, assembly, debugging, and technical support for various high-speed rotating machinery and various liquid working fluid oil systems;

4) Design, manufacturing, assembly, debugging, and technical support of hydraulic control systems and hydraulic stations.

5) Conduct experimental testing, optimize design, and provide technical support and services for the problems in the turbine oil system of in-service units.

2. Design, Complete project

2.1 Turbine oil system of steam turbine generator unit

1) Turbine oil source system;

2) Lubricating oil system, jacking oil system, sealing oil system;

3) Regulation, security control, and power oil source system;

4) Control, protection, and monitoring of oil source systems and equipment;

5) Complete set of supply oil system main and auxiliary equipment.

2.2 DEH fire-resistant oil EH system of steam turbine

1) EH oil source system;

2) Hydraulic air control and protection system;

3) Control, protection, and monitoring of oil source systems and equipment;

4) Provide complete sets of EH system main and auxiliary equipment.

2.3 Various liquid working fluid oil systems

1) Oil source system;

2) Lubricating oil system;

3) Hydraulic control and power oil source system;

4) The oil source system is difficult to set up collision control, household monitoring, and monitoring;

5) Complete set of supply oil system main and auxiliary equipment.

2.4 Hydraulic control system machine hydraulic station

1) Design specialized hydraulic control systems and hydraulic stations according to user needs;

2) Hydraulic cylinder, hydraulic Servomechanism;

3) Provide complete sets of main and auxiliary equipment.

3. Test verification

Having a first-class comprehensive testing station in China and a large-scale comprehensive testing station for regulating systems; Large oil system comprehensive testing station; Multifunctional overspeed test bench for steam turbines; Adjusting the component set test bench; Main oil pump test bench; Performance test bench for electro-hydraulic servo valves and servo valve systems; Valve, pump, cylinder test bench, etc. Provided a testing base for the design verification of oil systems and equipment. The main equipment and components designed, manufactured, and assembled in complete sets undergo performance assessment tests before leaving the factory to verify the correctness of design, selection, and manufacturing, as well as the performance and reliability of the equipment. The main equipment is also assembled and debugged as a whole to ensure smooth on-site installation and successful system startup.

4. Performance

1) As a supporting product of the manufacturing plant, the turbine oil system has been applied to 25MW, 30MW, and 50MW units, and the design of the turbine oil system for 150MW steam turbine generator units has been completed. The systems put into operation have all been successfully started at once, and after operation testing, all indicators have met the design requirements, ensuring the safe and stable power generation and supply of the unit.

2) We have provided the design of a turbine DEH fire-resistant oil EH system test bench for higher education institutions and research institutions;

3) Designed and developed various specialized hydraulic control systems and hydraulic stations, which have been successfully applied;

4) We have been conducting experimental testing, optimizing design, and providing technical support and services for the problems in the turbine oil system and equipment of in-service units for many years, providing guarantees for the safe operation of the units.

5) In addition to its domestic application, the turbine oil system has been exported to Türkiye, Syria, Indonesia and other countries together with the manufacturer.

.jpg)

024-23788883

024-23788883