Servo valve detection

According to industry standards such as electricity, electro-hydraulic servo valves must undergo regular testing to eliminate faults, eliminate hidden dangers, and ensure safe and stable operation of the unit through detection, diagnosis, and maintenance. To meet the needs of safety production, the company is responsible for the inspection and maintenance of electro-hydraulic servo valves.

1. Test equipment

1) Adopting an electro-hydraulic servo valve test bench designed according to national standards and technical requirements of the power industry;

2) The electro-hydraulic servo valve test bench has passed the certification of "National Laboratory Accreditation" and "General Administration of Quarantine and Inspection of the People's Republic of China";

3) Using phosphate ester flame retardant liquid as the working fluid, which is basically the same as the actual working fluid of the electro-hydraulic servo valve;

4) Equipped with simulation testing and computer-aided testing functions to perform performance testing on electro-hydraulic servo valves;

5) It has won 2 technical patents related to the electro-hydraulic servo valve test bench and 1 scientific and technological progress award from the original State Power Corporation of China.

2. Testing standards

1) National standard GB/T15623.1-2018 "Methods for Testing Electrohydraulic Servo Valves";

2) Electric power industry standard DL/T996-2019 Technical Conditions for Electro hydraulic Control System of Steam Turbine in Fossil fuel power station.

3. Detection content

3.1Detection object

1) Conduct performance testing and maintenance on various types of imported and domestic pantograph electro-hydraulic servo valves;

2) Regular cleaning, performance testing, and diagnosis of in-service electro-hydraulic servo valves to eliminate hidden dangers, replace aging seals, and replace filter elements with degraded performance;

3) Conduct performance testing on the new electro-hydraulic servo valve and adjust the corresponding parameters according to the requirements of the power industry standards;

4) Clean, repair, and adjust the corresponding parameters of the faulty electro-hydraulic servo valve to meet the standard requirements.

3.2Detection content

1)Detect the original state of the inspected electro-hydraulic servo valve, and carry out disassembly, maintenance, and troubleshooting based on the detection results of the original state of the electro-hydraulic servo valve. Adjust or repair the parameters of the electro-hydraulic servo valve whose detection results do not meet the operating standards.

4. Testing items

1) Rated current no-load flow characteristics (including rated flow, hysteresis, linearity, asymmetry, etc.);

2) Zero bias testing and adjustment;

3) Pressure gain characteristics;

4) Leakage within zero point;

5) Zero out of zone resolution.

5. Test report

1) The "Quality Inspection Center (HCTC)" provides performance test curves, pressure gain characteristic curves, zero internal leakage curves, zero external resolution curves, and pressure gain characteristic curve test data and conclusions for the electro-hydraulic servo valve flow characteristic curve, pressure gain characteristic curve, and zero external resolution curve;

2) Prepare a testing report for the electro-hydraulic servo valve with the confirmation of "National Metrology Certification (CMA)";

3) The testing report is internationally recognized and has only a certain legal effect.

6. Technical support

1) Establish technical archives for the tested electro-hydraulic servo valves;

2) Provide technical support for the installation, use, storage, and spare parts of electro-hydraulic servo valves;

3) Provide technical training on the principle, structure, operation, and maintenance of electro-hydraulic servo valves;

4) Based on the detection results of the faulty electro-hydraulic servo valve, comprehensively analyze the cause of the fault and provide technical support to users;

5) Conduct online analysis and research on the faults of the electro-hydraulic servo valve and EH system of the operating unit, and provide technical support for users.

7. Performance

7.1 Type of tested electro-hydraulic servo valve

The inspected electro-hydraulic servo valve basically covers various types of domestic and foreign in-service operation.

1) Imported electro-hydraulic servo valves inspected: MOOG Company's MOOG072, MOOG076, and MOOG078 series servo valves; PAKER415 servo valve from PAKER company; VICKER company series SM4 servo valve; ABEX Company's ABEX425 series servo valve; STAR HYDRAULICS 890 series servo valve; EMC EMC-8 servo valve; E-SYSTEM's 215A servo valve, as well as MOOG's D663 and D664 DDV valves.

2) Tested domestic electro-hydraulic servo valves: YFW06 and YFW18 series servo valves from Qinfeng Airlines; FF102 servo valve of Aviation 609 Institute; SF21 and SF18 series servo valves of Aviation 812 Institute; CSDM2-63 servo valve of CSIC 704 Institute; Shanghai Norma Company CS-RT761, RT7625M series servo valves, etc.

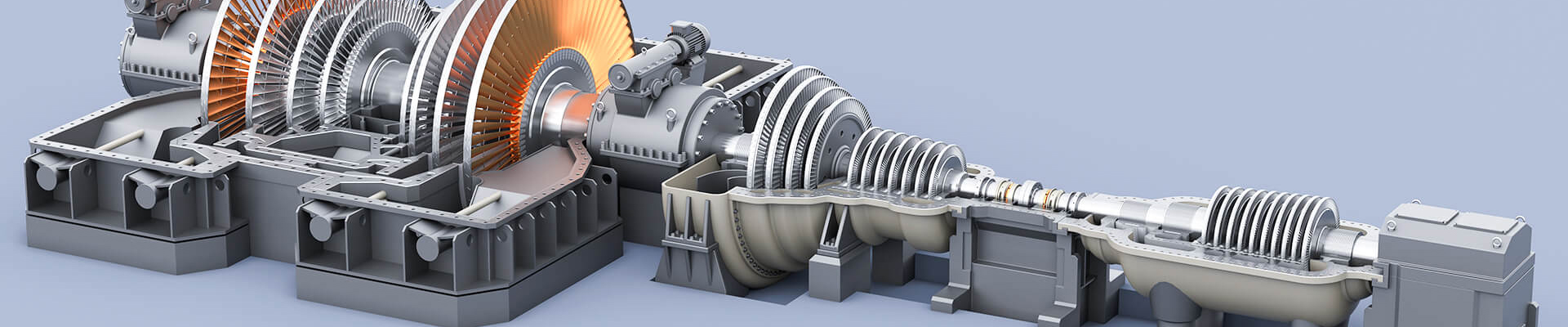

7.2 Overview of the inspected electro-hydraulic servo valve unit

1) The capacity of the inspected electro-hydraulic servo valve unit: 100MW, 110MW, 125MW, 135MW, 150MW, 200MW, 300MW, 330MW, 350MW, 600MW, etc;

2) Tested electro-hydraulic servo valve unit manufacturers: Harbin Automobile, Dongqi, SAIC, Beizhong, Wuhan Automobile, Nanqi, as well as various types of units produced by Hitachi, Westinghouse, GE, Alstom, Ansaldo, the former Soviet Union, the Czech Republic and other manufacturers.

.jpg)

024-23788883

024-23788883

.jpg)